1. He aha ka welded cylinder?Hoʻopili pololei ʻia ka barela i nā pāpale hope a hoʻopaʻa ʻia nā awa i ka pahu.Hoʻopaʻa ʻia a hoʻopaʻa ʻia paha ka ʻili o ke koʻokoʻo mua i loko o ka pahu cylinder, kahi e hiki ai i ka hui piston rod a me nā sila hoʻopaʻa ke wehe ʻia no ka lawelawe.Loaʻa i nā puʻupuʻu hydraulic welded nā mea maikaʻi ma mua o nā cylinders tie rod.ʻOiai ʻoi aku ka liʻiliʻi o ka hana ʻana i nā cylinders tie rod, ua manaʻo pinepine ʻia lākou i nā mea "ma waho o ka papa" a loaʻa nā koho liʻiliʻi e pili ana i ka hiki ke hana.ʻAʻole ʻoi aku ka lōʻihi ma mua o nā cylinders welded.Hiki ke hana ʻia nā ʻāpana kino Welded no nā noi kikoʻī.Loaʻa i nā puʻupuʻu welded nā pūʻolo sila ʻoi aku ka maikaʻi, hiki ke kōkua i ka hoʻonui ʻana i ke ola o ka cylinder a hiki ke pōmaikaʻi ke hoʻohana ʻia ka cylinder ma nā wahi e pili ana i nā mea haumia a me ka wā.Aesthetically, welded body cylinders he haʻahaʻa haʻahaʻa ma mua o ka tie rod cylinders a hiki ke hoʻomaikaʻi i ke ʻano o nā mea hana i hoʻohana ʻia ai.No ka mea ua ʻoi aku ka liʻiliʻi ma mua o ko lākou mau mea like, ua hana maikaʻi nā cylinders hydraulic welded i nā noi i mea nui ka lewa.

2. Pehea e hoʻomalu ai i ka maikaʻi wili i ka wā hana nui?

Lako wiliwili;E hoʻomākaukau pono i ka laʻana wiliwili e like me nā koi kaʻina hana i koho mua ʻia: Preheating, welding, mālama wela, a hoʻomākaukau i ka hāpana welding.A me ka hana ʻana i kahi kāleka kaʻina hana welding e hāʻawi i ke kumu no ka hoʻokō ʻana i ka welding;ʻO nā mea hoʻoheheʻe, ka uwea kuʻi a me ke kinoea hoʻoheheʻe he mau mea like, hana paʻa, hoʻomaʻemaʻe kinoea kiʻekiʻe, a me nā lakio pololei;kanaka welder, pono e loaa ka palapala welder;ʻO ka hoʻāʻo welding, e like me ka hoʻāʻo ikaika weld bead a me ka hoʻāʻo ultrasonic e nānā i ka maikaʻi wili.

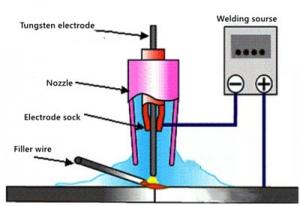

3. Hiki ke hoʻokaʻawale ʻia ka hoʻoheheʻe ʻana i ke kinoea i loko o ka inert gas shielded welding (TIG welding), hoʻoikaika kino kinoea hoʻoheheʻe ʻia (MAG welding).ʻIke loa, ʻoi aku ka maʻamau o ka argon ma muli o kāna kumu kūʻai ʻoi aku ka liʻiliʻi, no laila ua ʻike pū ʻia ke kuʻi kuʻi ʻana i ke kinoea pale ʻia me ka argon arc.ʻO Tungsten inert gas welding kahi hana hoʻoheheʻe kahi i hoʻohana ʻia ai ka tungsten a i ʻole tungsten alloy e like me ka mea electrode, a ʻo ke arc i hana ʻia ma waena o ka electrode a me ka mea kumu e hoʻoheheʻe ai i ka mea kumu a hoʻopiha i ka uea ma lalo o ka pale o ke kinoea inert. .

ʻO TIG, ka mea i kapa ʻia ʻo Gas Arc Welding (GTAW), he ala ia e hana ai i ka Arc ma waena o Tungsten electrode a me ke kumu metala ma lalo o ka pale kinoea inert i hiki ke hoʻoheheʻe ʻia ke kumu metala a me nā mea uea wili a laila welded.Loaʻa iā ia ka wiliwili DC TIG a me ka wiliwili AC TIG.

Lawe ʻo DC TIG i ka mana wiliwili DC arc ma ke ʻano he kumu mana wili, me ka mana maikaʻi ʻole a me nā kumu kumu maikaʻi.Hoʻohana nui ʻia ia no ka wili ʻana i ke kila kila, titanium, keleawe a me ke keleawe.ʻO ke kumu hoʻoheheʻe mana o ka AC TIG welding mai ka AC arc, a ua hoʻololi ka anode a me ka cathode o ka mea kumu.Hiki i ka EP polarity electrode overheating ke hoʻoneʻe i ke kumu o ka ʻili o ka oxide layer, i hoʻohana nui ʻia no ka aluminika, magnesium, a me nā mea hoʻohui ʻē aʻe.

I ka hana ʻana o TIG (GTAW), hiki i ka welder ke lilo i pū hoʻoheheʻe ma ka lima hoʻokahi a me ke kaula wili i ka lima, kūpono no ka hana liʻiliʻi a me ka hoʻoponopono ʻana i ka wili lima.Hiki ke wili ʻia ʻo TIG kokoke i nā metala ʻoihana a pau, hāʻawi ia i ke ʻano kuʻi ʻana maikaʻi, hiki ke hoʻohana nui ʻia ka slag a me ka lepo i ka pā hao lahilahi a mānoanoa.

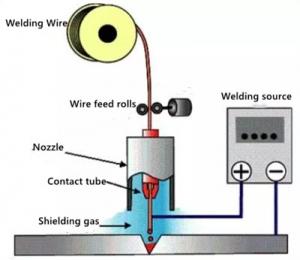

MAG (Metal Active Gas) Hoʻohana ka welding i ka CO₂ a i ʻole ka hui ʻana o argon a me CO₂ a i ʻole oxygen (he Active Gas).ʻO ka wiliwili ʻana o ke kinoea CO₂ i kekahi manawa i kapa ʻia ʻo CO₂ arc welding.ʻO nā mea hana wiliwili MIG a me MAG e like me ka hiki ke hānai ʻia mai loko mai o ka lama e kahi mea hoʻoheheʻe uea maʻalahi a kūpono no ka wili ʻana, ʻaʻole e haʻi i ka wili lima.ʻO ka ʻokoʻa nui ma waena o lākou aia i ke kinoea pale, ʻo ka mea mua i mālama ʻia e ke kinoea argon maʻemaʻe, kūpono no ka wili ʻana i nā metala non-ferrous;Hoʻohana nui ka MAG welding i ke kinoea CO₂, a i ʻole argon i hui ʻia CO₂ kinoea ikaika, ʻo ia hoʻi ʻo Ar+2%O₂ a i ʻole Ar+5%CO₂, kūpono no ka wili ʻana i ke kila ikaika a me ke kila kila kiʻekiʻe.I mea e hoʻomaikaʻi ai i ke kaʻina hana o CO₂weld, hiki ke hoʻohana ʻia ka CO₂+Ar a i ʻole CO₂+Ar+O₂ hui pū ʻia a i ʻole ka uea flux-cored.Hōʻike ʻia ʻo MAG welding e kona wikiwiki wiliwili wikiwiki, kiʻekiʻe arc initiation efficiency, hohonu hohonu, kiʻekiʻe deposition maikaʻi, maikaʻi hiʻohiʻona, hana maʻalahi, kūpono no ka wili kiʻekiʻe pulse MIG (GMAW).

Ua paʻa ka wikiwiki i ka R&D a me ka hana ʻana onā pahu hydraulica me nā ʻōnaehana hydraulic, lawelawe i nā mea kūʻai aku a hāʻawi i nā limahana i kahi ola maikaʻi aʻe.I kēia lā, ua kōkua mākou i nā tausani o nā mea kūʻai aku ma ka honua holoʻokoʻa e hāʻawi ana i ka ʻike i ka hydraulic cylinder a me ka hoʻolālā ʻōnaehana me nā pono hoʻokūkū.

Ka manawa hoʻouna: Sep-16-2022